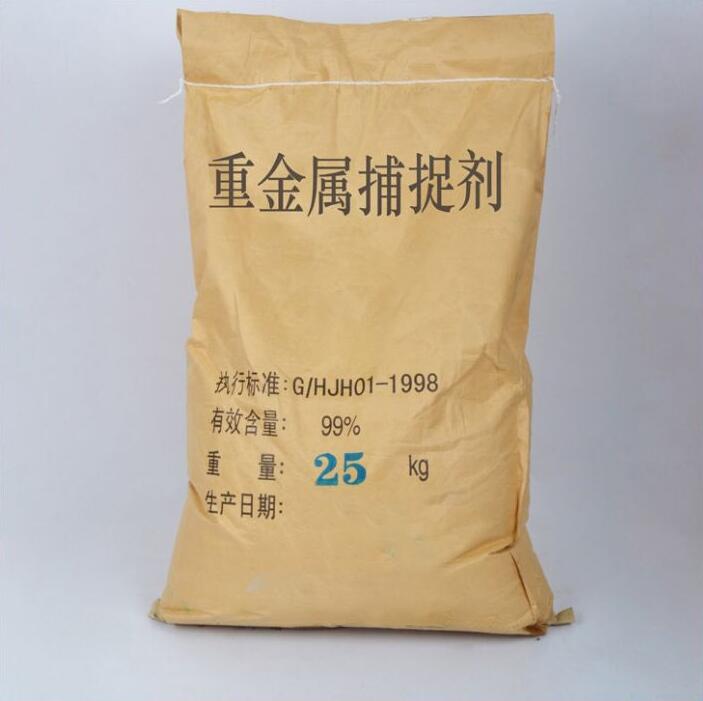

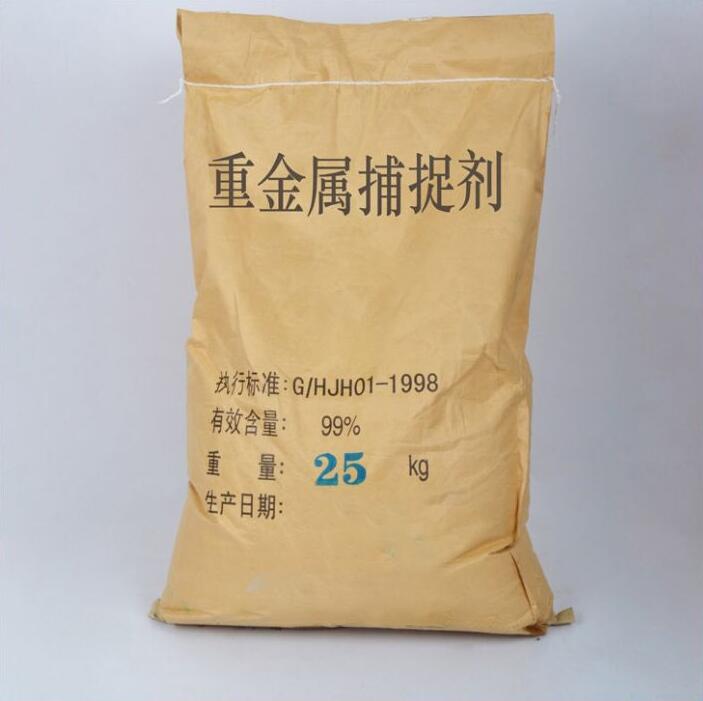

heavy metal scavenger

Applications:

1. Removal of heavy metals in wastewater treatment of electroplating plants;

2. Removal of heavy metals in wastewater treatment of electronic circuit board factories;

3. Removal of heavy metals in mine tailings wastewater treatment;

4. Removal of heavy metals in metallurgical wastewater treatment;

5. Removal of heavy metals in wastewater treatment in chemical and leather industries.

Instructions:

The heavy metal scavenger can be added in the conventional treatment process. It is easy to mix and dilute with water. Therefore, it can be diluted with water to any desired ratio to meet the capacity requirements of the feed pump. High quality dilution water should be used, with a pH close to neutral. This product can be used in areas of high turbulence, such as the suction port of a pump. In fact, when heavy metal scavenger is added to the solution, the treated water should be stirred to make the metal precipitate fully react before precipitation.

Storage tanks can be made of polypropylene, stainless steel (304 or 316) or high-density heterocyclic polyethylene (HDCLPE). Recommended piping and mounting materials are rigid PVC, stainless steel, HDCLPE, polypropylene, Viton, Buna N, and polyethylene. Avoid carbon steel, brass, zinc and other metallic materials for piping and storage tanks.

Copyright © 2014-2024 Shenzhen JingZhuoKe Chemical Technology co., LTD All Rights Reserved Site map